Forge Building Part 2 - The Firebox

March 2018

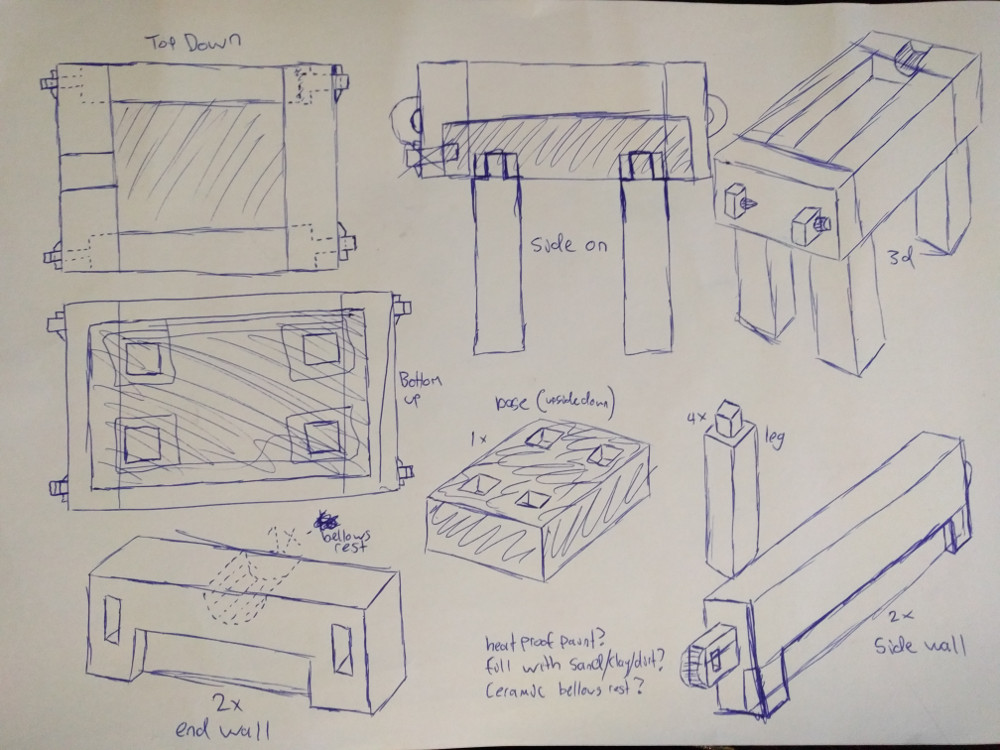

For my historical forge, I wanted to ensure that it would be very resilient, portable and use historical construction techniques as much as possible. I also massively over-engineered it, the firebox itself ended up weighing more than one of my smaller anvils. I started out with a rough idea of how I wanted to build it (after making and reworking several plans). I also started this with almost no experience in woodworking.

Firstly I purchased a couple of 2.4m lengths of seasoned 190x45mm hardwood.

Then I made liberal use of a big overhead router and table saw at a local maker space (aptly called MakerSpace). My plan at this stage was to use sliding dovetails to fit the ends to the sides, however, the receiving side ended up snapping on the first test fit so I promptly scrapped that idea.

I then opted to use a regular dovetail join, on a scale large enough for the wood I was using. Following my first attempt at dovetailing, I got some practice in with my partner’s parents while we were staying over for Christmas.

It took some time to make the dovetailing joins on the larger pieces, however, I got there in the end. A side effect of changing the join mid-project is that the ends do show the channel that I made for sliding the base in.

It took some effort and a false start, but the outcome is a solid firebox, that will easily take abuse.

I have not weighed it, however, I estimate that it is at least 20 KGs. It’s easily big enough to contain a decent sized fire without the danger of burning the firebox itself. I plan to document further progress in building my historical forge.